Strength of Material

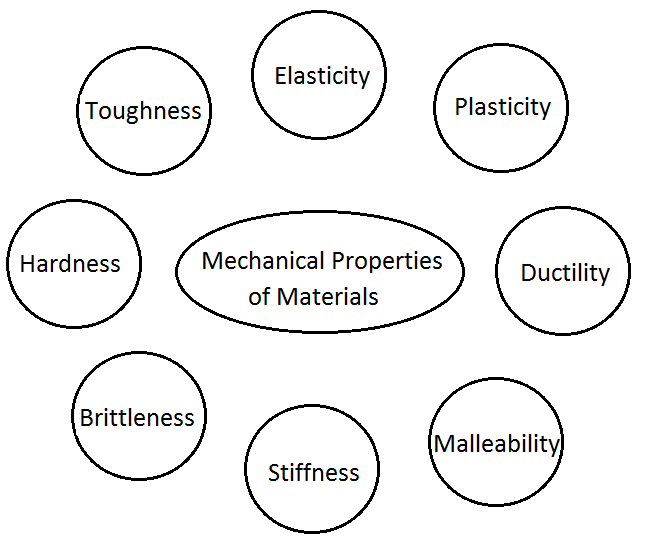

Mechanical Properties

- Hardness ;Resist the penetration (impact load)

- Strength : Ability of material withstand of material without failure.

- Elasticity : It regain the original shape after removing load

- Plasticity : Permanent deformation after removing load.

- Mali ability : Converts to thin sheet without rupture

- Ductility : Draw in to thin wire.

- Brittleness : No deformation takes place & rupture (lake of ductility ) (cast iron)

- Toughness : absorb energy & plastic deformation without rupture.

- Fatigue: by repeatedly applied load program me and localized structure damage that occur.

- Creep : tendency of solid material to move slowly deform permanently under mechanical stress.

Stress : Load applied on particular area.

- it is tensor quantity

- unit : N/mm2

- it has no unit.

Strength of Material

Tensile : when body is subjected to equal and opposite pull.Compressive : when body is subjected to equal and opposite push.

Thermal stress : stress due to change in temperature.

Linear strain : deformation of bar per unit length in direction of force.

Lateral strain : Direct stress dis accomplished strain in its own direction & opposite kind of strain in every direction at right angle is known.

Poison 's ration = Lateral strain / Linear strain

- it has no unit

- max poison ratio = 0.5 (rubber)

E = 9KC /(3K+C)

Principle stress & strain:

- 3 planes are mutually perpendicular to each other

- Carries direct stress only

- No shear stress

- 3 direct stress (Max, min, intermediate)

Resilience: Strain energy stored in body due to external loading with in the elastic limit.

Bending Assumption :

- Material is homogeneous.

- obey hook's law.

- Transverse section plane before and after bending.

- Each layer is free to explained.

- Value of young s modulus is same in tension and compression.

Strength of Material

Bending equation:(M/I)=(SIGMA /Y)=(E/R),

M= Bending Moment

I = Moment of inertia

Y = Distance from center

E = Young 's modulus

R = radius of curvature

Shear stress in shaft

(Tou/R) = (T/J) = (C x thita )/l

Tou = Shear stress

R = Radius of shaft

T = torque

J = polar moment

C = Rigidity

thita = angle of twist

l = length of shaft

Stiffness of spring : load required to produce unit deflection in spring is called stiffness of spring.

vipul baria

Comments

Post a Comment